That is unless there’s no food on the shelves.

Earlier this month, Business Insider broke a startling story about chronically sold-out items and depressingly empty aisles in Whole Foods locations across the United States. Pictures that accompanied the article revealed a bleak consumer landscape: bare shelves in New York, a meager butcher’s selection in Boston and a cleaned-out freezer in San Francisco. Customers interviewed were disappointed. Store employees were distraught. “At my store, we are constantly running out of products in every department,” said one assistant manager.

The culprit? A newly adopted inventory management tactic called “order-to-shelf” (OTS), which more or less skips over the storage middleman and consolidates corporate buying practices in an effort to cut waste and slash prices.

But despite these good intentions, certain Whole Foods staff members feel something is being lost in translation. Spoilage may be low, but anxiety is high. “The system is now set up to [have only] enough product to keep the shelf full and no extra,” said one Whole Foods worker, who went on to describe a depleted back stock that was only one-quarter of what it used to be.

The lesson here? Even a conglomerate like Whole Foods (recently overtaken by an even bigger conglomerate you may have heard of: Amazon) can have trouble striking the right inventory balance. The grocery giant, like every other retail organization, constantly faces that age-old question: How do you control your inventory in a way that reduces overages and prevents obsolescence but still protects you from panic-inducing shortages?

The solution? Well, …it varies from business to business. Still, there are a few tried-and-true practices that can help retailers ensure against inventory disaster and keep stocks at optimum levels.

Here are our top picks for the best ways to manage and maintain your inventory so you’ll never have to stress too much over empty shelves or outmoded back stock ever again.

Know what you have on hand.

Shopify blogger Casandra Campbell perhaps puts it best: “Inventory is a placeholder for money.” Your inventory simultaneously represents cash spent and cash to be earned. Get to know it the same way you’d get to know your profit and loss statements. Make it part of your job to review what you have in store, in stock, and in your warehouses. A proactive interest in what you have available can mean the difference between a healthy supply and a dangerous demand.

Some easy ways to track of your inventory include

cycle counting

(in which products are periodically checked against inventory lists to ensure all records are accurate and to alert retailers to buyer trends), barcode scanning and/or an exhaustive physical tally of anything and everything your business has to sell (usually conducted on a yearly basis). Already freaking out at the thought of all that math? An inventory management software solution can be a useful ally. Comprehensive management services and digital coding will enable you to keep an eye on sales, orders, stock levels, transit details and other forms of inventory logistics.

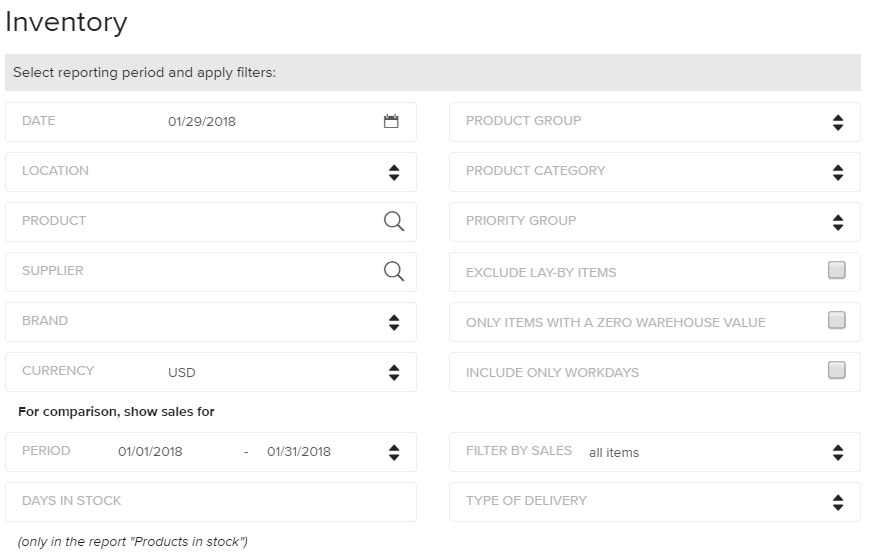

Erply’s powerful reporting engine gives you multiple options for evaluating and managing inventory.

Understand your buyers and their tastes.

Your customers make up a significant portion of your inventory equation. Don’t be shy. Go ahead and introduce yourself.You should always be just as acquainted with your buyers’ behavior as you are with your products. Why? Because an extensive knowledge of your customers’ demographics and purchase histories can help you stay ahead of the curve when it comes to deciding what to restock and when. This info leaves you less vulnerable to “sold-out” scenarios and enables you to anticipate consumer mood swings.

Do your due diligence and familiarize yourself with the ebbs and flows of your sales according to weekly, monthly or seasonal landmarks. If you notice a particular item flies out of your stores on a given holiday, take note. If you’re enjoying a steady increase in sales and think there’s nowhere for your company to go but up, a file that thought away for future reference. Shopify recommends you check in on overall growth and market trends as well since these can also provide an indicator of what will sell (and what won’t) in the coming months. The e-commerce expert also suggests you remember to factor in guaranteed sales (i.e., subscriptions, pre-orders, standing orders, etc.) as these figures still affect your stock levels, even if you can’t see the impact in real time.

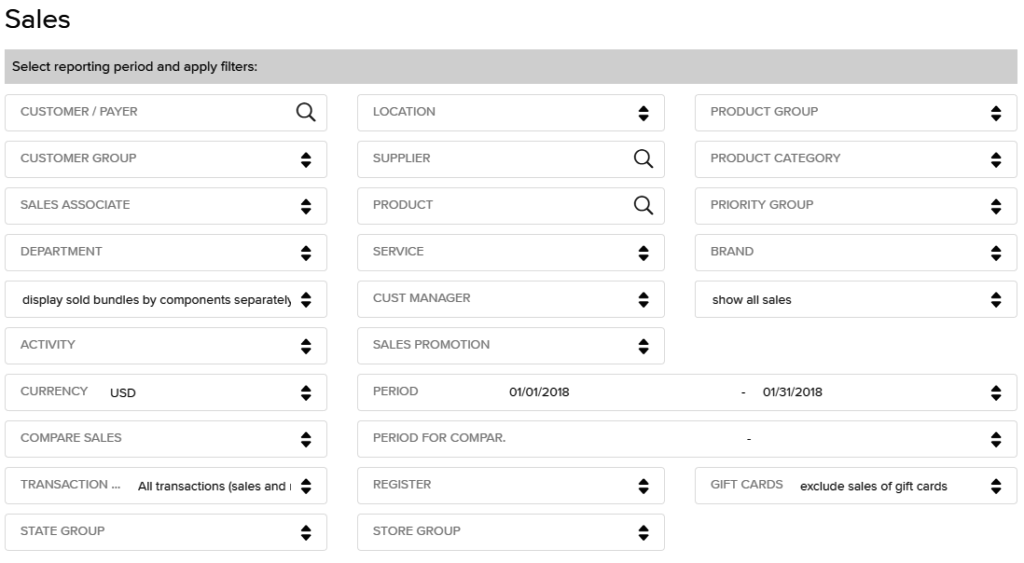

What’s selling, and what’s not selling? In which locations? Which general categories or brands? How are promotions impacting sales? In Erply you have quick access to find details about how quickly you’re moving inventory, so you can make smart decisions about what to keep in stock.

Don’t be subpar: Have a Plan B…and C…and D…

According to Business Insider, a possible glitch in the Whole Foods OTS system is that it makes very few allowances for human error, natural disaster or any other type of bump in the business road. Employees reported that OTS inventory management means less backup stock on site, which means more stores are at risk of not being able to meet customer demand. If just one wheel in the inventory machine stops spinning, the shelves start to clear faster than supplies can keep up—leaving customers stranded and brand reputation in potential trouble. “If a truck breaks down and you don't get a delivery, then you have empty shelves,” one Illinois Whole Foods assistant manager noted. How to sidestep these kinds of inventory interruptions? The key is to be prepared. Come up with an effective plan B in the event of unforeseen disruptions. Give yourself a cushion in case things go wrong and the unthinkable becomes reality.

Once your plan B is in the books, create a plan C. And a plan D. You can never be too careful or too well equipped for an unexpected gap in inventory coverage.

One method for combating a sudden sell-out is to institute mandatory minimums for your products. These minimums, known as “PAR levels” (Periodic Automatic Replenishment levels), provide instant stock protection and safeguard against immediate catastrophe. If you never let product numbers fall below a certain point, you’ll never be caught completely off guard or be left with absolutely nothing to sell (barring any market anomalies, of course).

Other emergency strategies include having extra suppliers on standby (see our thoughts on fostering a healthy supplier relationship here [link to blog post on supplier relationships]) or saving your inventory files on a regular basis. “Your backup plan can be as simple as saving critical data to a removable thumb drive,” Lisa Girard of Entrepreneur.com writes. When it comes to contingency plans, you don’t necessarily have to think big, but you do have to think smart.